Revit Family Creation

A component of effective Revit Family Development Services is the complete life cycle of construction knowledge modeling (BIM).

Revit Family Creation.

A component of effective Revit Family Development Services is the complete life cycle of construction knowledge modeling (BIM). AEC BIM Services LLC is the leading outsourcing company for BIM that practices and complies with all the international codes and standards needed for BIM projects to be completed.

A pragmatic building model is the “components” that are built in this process, and this whole process is known as “BIM Components.” Revit is one of the most widely used BIM modeling applications, so it is often referred to as Revit Families

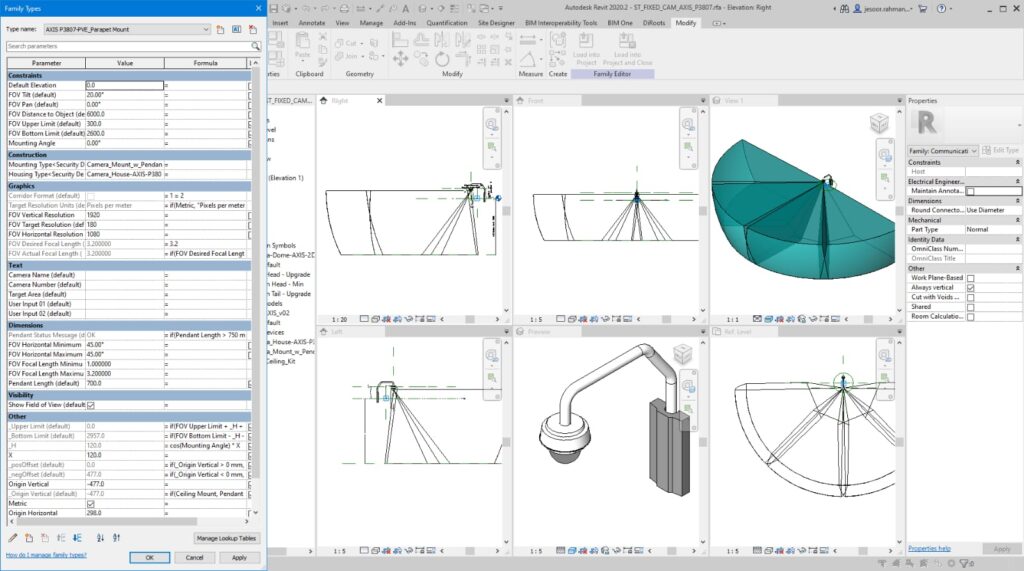

By using the Revit family editor method, the performance of BIM Family Development is carried out. With the aid of the family editor utility, all the elements and contents that are generated in this family are done without any kind of restriction and along with the use of parameters, the work becomes simpler, quicker, and faster. In order to build and develop a smooth user interface, the team of developers and the people who are using Revit for the first time can easily and reliably use this tool. “At AEC BIM Services LLC, we are the leading and one-stop destination for the delivery and understanding of the overall process of “Revit Family Formation.

Types Of Revit Family Creation Services

System Family Or Default Families

In the Revit program, these machine families are previously incorporated into it. The framework is integrated into these families and can therefore not be used in different interfaces or models. In addition, one of the facts is that the program does not uninstall this machine family or default families. These families are preferably used to build all the simple 3D models in which the specifics of where the placement will be performed with these families need to be shared.

Although it is a fact that there are different characteristics and properties of the device families, the basic root and characteristics will remain the same.

Loadable Families

Loadable families are widely used in the method of BIM Modeling. These are the families that are individually generated for each particular user interface or model requirement. They can be used in different user interfaces with a similar configuration, and can also be marketed to distributors or product design firms as separate families.

Another term for the families of Loadable Revit is known as part families. It is the BIM engineers who can update, build or remove the families, or the service provider of Revit family creations. These may also be some of the criteria that require the user interface or model requirement if there is a need to change the families. With the aid of a family editor, the customization of loadable families is simpler and faster.

Loadable families are the ones that, according to nature’s needs and conditions, can be nested. At AEC BIM Services LLC, we offer the entire BIM project that can be applied to the specifications based on restraints and parameters. Families with Revit may have differences with each family. The family types can be introduced in the later phase of the project with the help of the family editor method.

Parameters can be introduced that continuously regulate the presence of a specific family. Dimensions, examples, materials, visibility, and other specifics are some of the knowledge. You can insert the overall project environment and then adjust and load it on the model later. One of the most powerful features available in Revit is this. The family editor tool feature can easily be used and is used in families for BIM content.

In-Place Families

The type of families that are very similar to loadable families are In-Place families, but there is one of the main differences. The In-place family mechanism is that it can not be created or can be used as a stand-alone family, but these families are the ones that can be developed, edited, and preserved in the model for which the family’s place is hosted. There will not be any different .rfa files created when working on in-place families.

In-place families are simpler and easier to build and can effectively strive for the function if the model is distinctive and dynamic in nature. We and our team of engineers are sure to use these in-place families that are mindful of the family’s meaning and are still called default families. With the aid of this family support, the construction of walls, roofs and floors can be created using in-place families.

Nested Families

We will help you serve the next form of family development service and that’s families that are nested. When BIM modelers want to construct complex geometry using different and various types, the method of nested families is used. Often it is really important to take into account the use of nested families for the complexities of geometries. It is like the development and insertion of the family into another family is the nested family. In addition, it is not at all incorrect to suggest that we can operate and manage families with good versatility and overall control with the formation of nested families.

These are some of the types of resources for the development of the Revit family that play a vital role in the entire BIM project completion process. In addition, we at Silicon Valley understand the value of the service and thus provide the update and clarification for the development of the Revit MEP family.

BIM Fabrication And Pre-Fabrication Services

We use BIM, which is an intense process involving synchronizing data (data) and re-examining the way you work together. We have grasped this cutting edge strategy and are repeating the advantages already on board. We have had to be professional and streamlined, saving time and resources, while mitigating risk and expanding benefits for our business and our valued clients.

BIM combines all types of components, such as BIM prefabrication and manufacturing. BIM manufacturing is a method that promotes the creation of development materials or congregations using digitized data. BIM Prefabrication is a key benefit of enabling BIM to extend the use of prefabrication and modularization, thus improving the productivity of the workplace and the overall enterprise.

In the future, BIM will allow them to use prefabrication on larger, more perplexing projects. Likewise, the tremendous growth in green building has undeniably influenced the construction sector. In sheet metal fabrication, structural steel fabrication, pipe cutting, prototyping for design purpose surveys, and so on, a few uses of BIM manufacturing can be found. It helps to ensure that the downstream assembly cycle has the least ambiguity and ample data to generate zero waste.

Potential Values For BIM Fabrication And Prefabrication :

Quality of Knowledge Guarantee.

Minimize resistance through the manufacturing and prefabrication of machines.

Expand quality and protection in manufacturing and prefabrication

Decrease Lead Time.

Adjust to late design modifications.

The reliance on 2D paper sketches will be reduced.

AEC BIM Services LLC is the world’s leading organization providing cost-effective pricing for BIM production and prefabrication services all over the world. We have a team of experts who manage and have the ability to understand and construct models of manufacturing and prefabrication, to explore and manipulate and survey a 3D model, to generate building materials using advanced information, to derive computerized information from 3D models for manufacturing and prefabrication.

You can go ahead and contact us for any kind of solutions you are looking for BIM Prefabrication and Manufacturing and we will be there for you to solve it with the help of our BIM team of experts. We’re going to be there for you 24 * 7. Silicon Valley is proud of its ability to deal with a process of design creation, manufacturing process and prefabrication that improves the work we are able to create. Looking for consulting services from BIM? Call us!