BIM Coordination and Clash Detection

To serve as the BIM Manager of the project from Design, construction through submitting for operation.

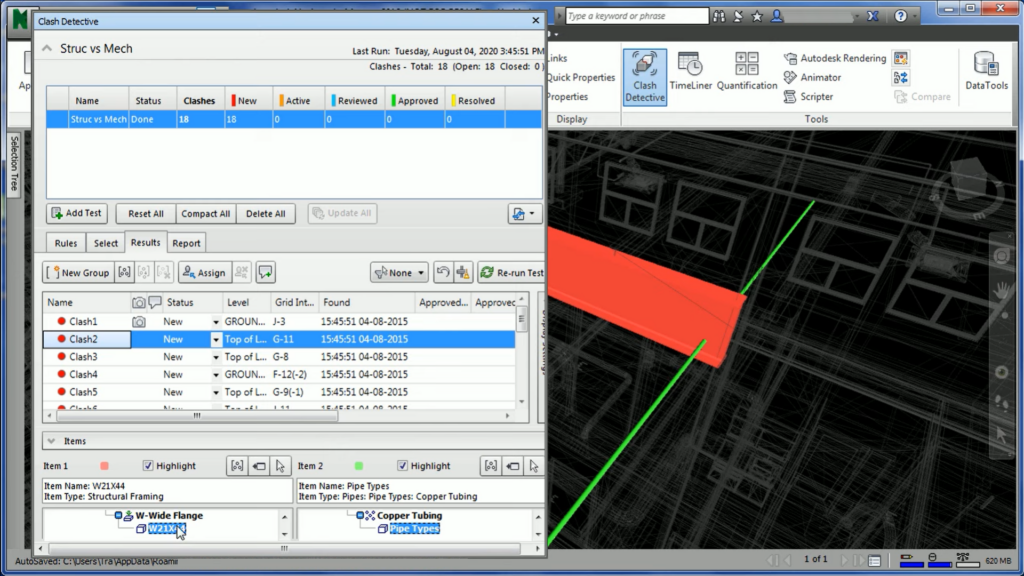

BIM Coordination and Clash Detection

In order to enhance interdisciplinary cooperation, minimize delays, material waste and expensive construction rework, BIM clash identification with 3D communication techniques foresees clashes at the initial stage of the project.

Up to 7.25 percent to 35 percent of overall project cost is added by rework and material waste and construction time is also increased. Tools for BIM clash detection, such as Navisworks, recognize, inspect and report clashes from federated 3D models generated by combining different disciplines into a shared platform. At the initial level, detecting and solving clashes minimizes cost, effort and time.

Why do clashes happen?

Clashes postpone construction until stakeholders coordinate to address the problem together. This irreversibly affects the expense and timetable of the project. Clashes occur because of:

- -Intersecting components of various disciplines that occupy the same space

- -Lack of buffer space around facilities

- -Conflict between workflow and scheduling of equipment

Clashes Identification and Resolution

By identifying and resolving areas of conflicts, the use of clash detection software such as Navisworks can promote 3D collaboration between disciplines and generate conflict reports. Before they proceed to the final construction level, clashes found prior to implementation can be reviewed, approved and resolved.

3 Clash Detection Categories

- Hard Clash

Hard Clash consists of two components sharing the same site, such as a duct that runs through a plumbing line or a steel beam pipework. Based on geometry or semantic and rule-based algorithms on the BIM object with embedded knowledge, hard clash detection can be detected.

Tools such as Navisworks recognize conflicts such as a beam running through a pipe for geometry-based detection, while the rule-based clash detection on embedded object data removes common mistakes such as a pipe running through a wall or MEP against a ceiling.

- Soft Clash

If an element does not need spatial or geometric tolerance, or its buffer zone is breached, Soft Clash results.

To enable maintenance at a later level, spatial tolerance criteria are typical in MEP services. For example, for secure and easy maintenance access, an air conditioning unit can require buffer space from a beam.

Soft clashes can cause maintenance issues and safety concerns if left unattended. If for example, a live wire passes through a plumbing line, there is always a chance of completion of the circuit or short circuit problems.

Providing applications such as Navisworks with appropriate object-related tolerance data will recognize clashes according to relevant regulations and standards. In order to ease operational maintenance, this will particularly apply to high occupancy locations such as malls, airports and healthcare facilities.

- Workflow or 4D Clashes

Workflow or 4D disputes include contractor scheduling clashes, distribution of equipment and supplies, and conflicts over the general workflow timeline. 4D clashes result from scheduling clashes of inter-disciplinary activities that ultimately reduce the productivity of the entire construction company, unlike hard and soft clashes. Since one dispute has a cascading impact on many disciplines and can bring work to a standstill, contractors can not afford 4D conflicts; BIM can be preferred.

In Navisworks, the creation of a 4D construction sequencing timeline points out the start and end date of each operation and assists the contractor to plan the activities accordingly. In 4D BIM, a structured step-by-step phase removes the risk of encountering any workflow conflict and prevents site downtime to sustain the task force’s man-efficiency.

Clash Detection Benefits

The architect’s model is used by different disciplines such as structural and MEP engineers as a starting point to create their own independent model to prevent disputes during the Design Creation Process.

The following advantages are: Clash identification on 3D organized models:

- Reduction of mistakes

- Because of specific figures in all phases of construction, a better construction site

- Reduction in overall expense, waste of materials and risk reduction

- Scheduling and sequencing enhancements

- Increase in performance and acceleration of the building process

For better communication, the models and data generated by different disciplines can be merged into a master model or into a common data setting.